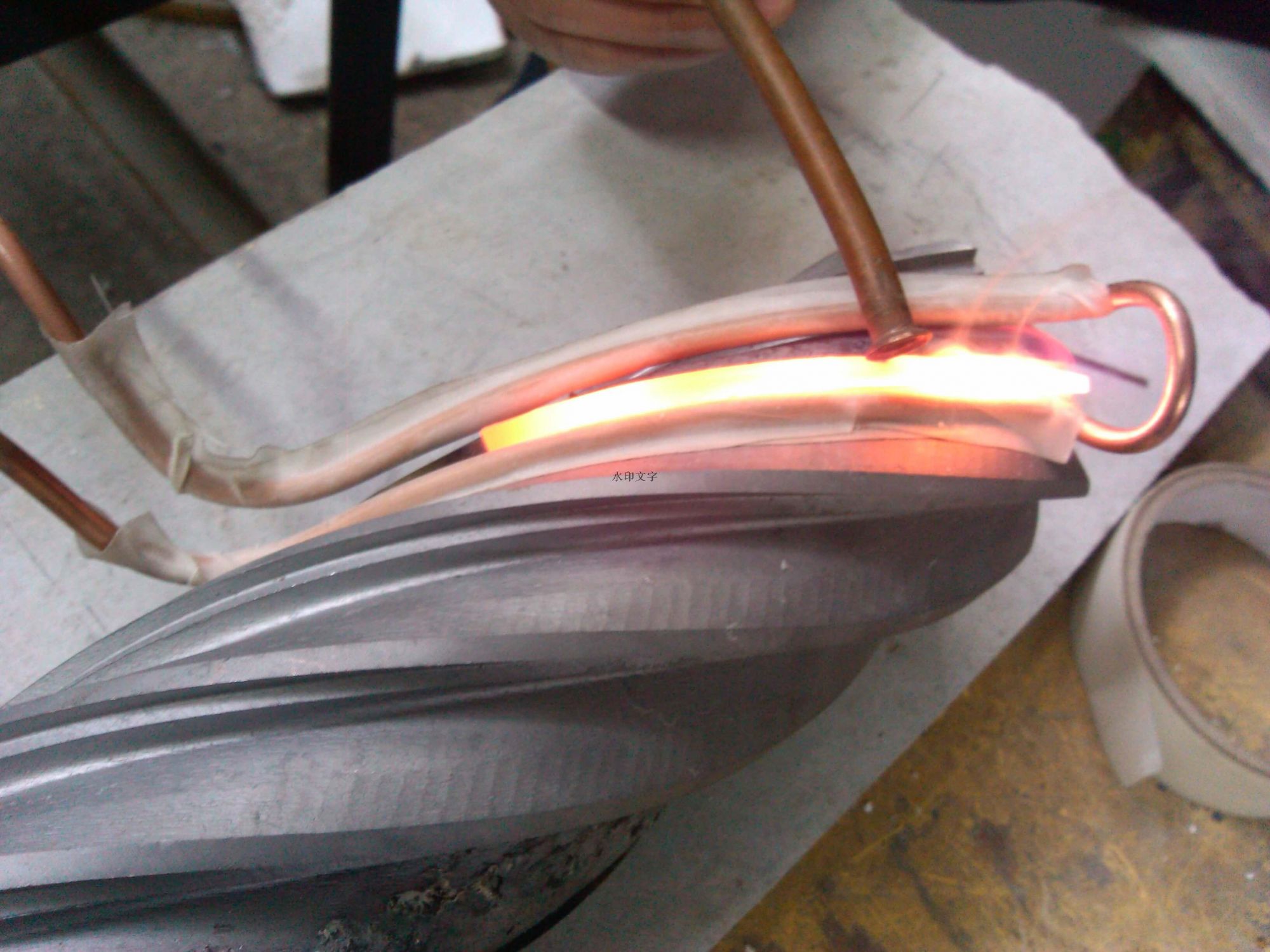

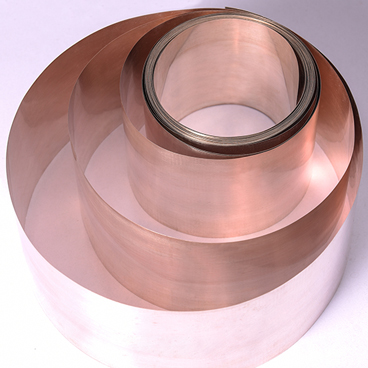

The welding methods of brass are: gas welding, carbon arc welding, manual arc welding and argon arc welding.

1. Gas welding of brass

Because the temperature of the gas welding flame is low, the evaporation of zinc in the brass is less than that of the electric welding, so in the brass welding, the gas welding is the most commonly used method (thank you for your attention to the automatic welding).

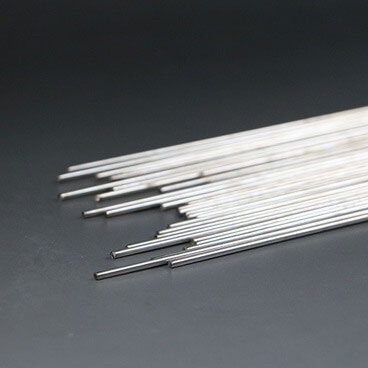

The welding wires used for brass gas welding are: wire 221, wire 222 and wire 224, etc. These welding wires contain silicon, tin, iron and other elements, which can prevent and reduce the evaporation and burning loss of zinc in the molten pool, which is conducive to ensuring the performance of the welding seam and preventing the generation of pores.The fluxes commonly used in gas welding brass are solid powder and gas flux. The gas flux is composed of methyl borate and methanol.Flux such as gas agent 301.

2. Manual arc welding of brass

In addition to copper 227 and copper 237, self-made electrode can also be used for welding brass.

When brass arc welding, direct current power supply should be used, and the electrode should be connected to the negative electrode.The surface of weldment should be carefully cleaned before welding.The groove Angle should not be less than 60~70 ° in general. In order to improve the weld forming, the weldment should preheat 150~250 ° C.The operation should be short arc welding, not transverse and back and forth swing, only for straight line movement, welding speed should be high.Brass welds in contact with corrosive media such as sea water and ammonia must be annealed after welding to eliminate welding stress.

3. Manual argon arc welding of brass

Brass manual argon arc welding can use the standard brass wire: wire 221, wire 222 and wire 224, can also use the same composition of the base material as the filling material.

Welding can be either direct current or alternating current.When AC welding is used, the evaporation of zinc is lighter than when direct current welding is used.Usually do not preheat before welding, only when the thickness of the plate is relatively large.Welding speed should be as fast as possible.The welding parts should be heated at 300~400℃ for annealing treatment after welding to eliminate welding stress to prevent cracks in the welding parts during use.

4. Brass carbon arc welding

In carbon arc welding of brass, wire 221, wire 222, wire 224 and other welding wires are selected according to the composition of the base metal, and self-made brass welding wires can also be used.Welding can use gas agent 301 as flux.Welding shall be performed with a short arc to reduce evaporation and burn loss of zinc.

sales@welding-material.com

sales@welding-material.com