Brazing is a method of connecting welding parts by using metal materials with lower melting point than welding parts, heating the welding parts and the filler metal to a temperature higher than the melting point of the welding parts and lower than the melting point of the welding parts, wetting the base metal with liquid solder, filling the joint gap and diffusing each other in the base metal.According to the melting point of the solder, there are: soft brazing, that is, the melting point of the solder is below 450℃;Brazing, i.e. the melting point of the solder is above 450℃.According to the height of brazing temperature, there are: high temperature brazing;Medium temperature brazing;Low temperature brazing.For brazing different materials, the classification temperature is different.According to the heating method, there are: flame brazing;Brazing in furnace;Induction brazing;Resistance brazing;Soldering, etc.

The adaptability of brazing is wide, it can weld most metals and some non-metals.Good brazing accessibility, for the space can not reach the weld, brazing can be completed;High precision of brazing, for high precision, complex parts, multiple welds, can be completed once, high efficiency;The heating temperature of brazing welding is much lower than that of fusion welding, which has little influence on the microstructure and properties of base material.The deformation of welding parts is small, especially the brazing with uniform heating, the deformation of welding can be reduced to the minimum, easy to ensure the dimension precision of welding parts.There are some disadvantages of brazing, such as low strength;Poor heat resistance;As most of them are superimposed type (lap joint) joints, increase the consumption of the base material, joint bulky.

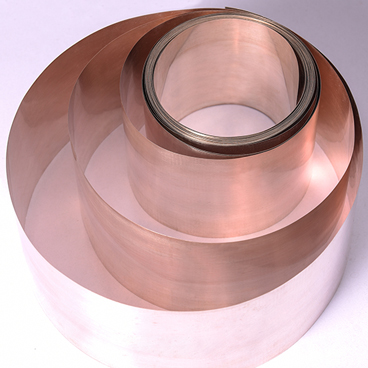

The filler metal is used to form the brazing joint during brazing.It is divided into soft solder (below 450℃), hard solder (above 450℃) and high-temperature solder (above 950℃) according to the melting point.According to the chemical composition (metal elements) : called "×" filler metals, such as nickel filler metals, tin filler metals, silver filler metals, etc.Flux, also known as flux, removes oxides from the surface of the base metal and liquid solder, protects the base metal and solder from further oxidation during heating, and improves the wettability of the solder on the base metal surface.Similarly, brazing agent with brazing filler metal can be divided into soft brazing agent and hard brazing agent.According to the use can also be divided into: aluminum flux;Powder brazing agent;Liquid brazing agent;Gas brazing agent;Brazing paste;Free cleaning flux, etc.

Brazing is mostly carried out by brazing filler metal in combination with brazing agent, but some brazing is carried out directly without brazing agent.During brazing, the strength of the front joint is lower than that of the base material. In order to increase the strength, the form of lap joint is usually adopted. Generally, the length of lap joint is 3 ~ 4 times of the plate thickness, but not more than 15mm.Most pipes are brazed by socket.Before brazing, use mechanical or chemical methods to clean the oxide film and dirt on the surface of welding parts. In order to prevent the free flow of liquid filler metal, a flow inhibitor is often applied on the surface of welding parts.When the clearance is too large or too small, the function of capillary will be affected, so that the strength of brazing joint will be reduced, and brazing joint will waste filler metal.

The technological parameters of brazing mainly include brazing temperature and holding time. The brazing temperature is generally 25 ~ 60℃ higher than the melting point of the filler metal, and too high or too low temperature is not conducive to ensuring the quality of brazing joint.The brazing holding time should be enough for the welding metal to interact with the filler metal. The interaction between the filler metal and the base metal should be shorter.The clearance is large, the welding part size is large, take longer.After welding, most of the residue of brazing agent has a corrosive effect on brazing joint, which also hinders the observation of brazing joint, so it must be cleaned up.

sales@welding-material.com

sales@welding-material.com