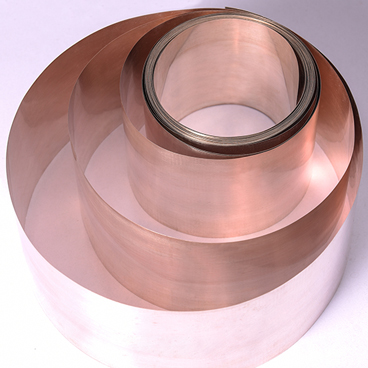

The size of brazing clearance has great influence on the capillary caulking, brazing density and brazing joint strength.When other process conditions are determined, the minimum feasible clearance can be selected to obtain the maximum strength of the joint.In this case, capillarity is significant and the liquid metal tends to fill the entire street gap to produce joints with fewer cavitating defects.The shear resistance of the joint reaches the best state.

Brazing is made by using the filler metal to fill the gap. The size of the gap affects the brazing density and joint strength to a great extent.

If the clearance is too small, it will be difficult for the solder to flow into the brazing joint due to the uneven contact surface, resulting in slag inclusion and lack of brazing penetration in the brazing joint, resulting in the decrease of joint strength.If the brazing clearance is too large, the clearance capillarity will be weakened and the filler metal cannot fill the clearance, which will also make the joint density worse and weld strength lower.Only by ensuring reasonable street clearance can capillary action be carried out smoothly and obtain the best effect.

In actual production, most of them are welding between different kinds of materials. In the design, the influence of expansion coefficient on the street clearance at brazing temperature must be considered in addition to factors such as whether brazing agent is used, the degree of action between base metal and solder, the liquidity of solder and the position of the street, etc.

sales@welding-material.com

sales@welding-material.com